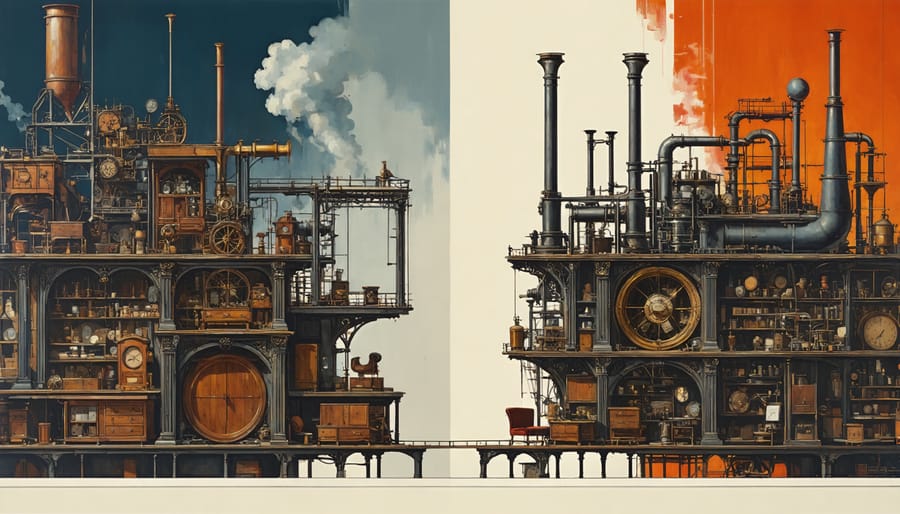

The Second Industrial Revolution transformed not just how we make furniture, but how we live with it. Between 1870 and 1914, groundbreaking innovations in steel production, electricity, and mass manufacturing revolutionized furniture design and accessibility. Gone were the days of purely handcrafted pieces – new industrial processes made stylish, durable furniture available to the growing middle class for the first time in history.

This period introduced game-changing materials like bent steel, mass-produced wood components, and early synthetic materials that still influence modern furniture design today. The assembly line techniques pioneered by Henry Ford weren’t just for automobiles – they fundamentally changed how furniture was conceived, manufactured, and distributed. From the iconic Thonet bentwood chair to the first mass-produced office desks, these innovations created the foundation for today’s furniture industry.

Understanding this pivotal era helps us appreciate both the heritage pieces we restore and the manufacturing principles that shape contemporary furniture design. The Second Industrial Revolution’s legacy lives on in every precision-cut component and streamlined production process we see today.

The Second Industrial Revolution brought unprecedented changes to furniture manufacturing, transforming what was once a craft-based industry into a highly efficient production system. Steam-powered machinery and assembly line techniques enabled factories to produce furniture at rates previously unimaginable. This mass production revolution made furniture more affordable and accessible to the growing middle class, who could now furnish their homes with items that were once reserved for the wealthy.

New manufacturing processes, such as the development of the band saw and automated wood-turning lathes, allowed for consistent, precise cuts and standardized components. These innovations led to the creation of interchangeable parts, making furniture both easier to produce and repair. The Thonet bentwood chair, introduced in the 1850s, exemplifies this transformation – its revolutionary steam-bending technique allowed for the mass production of elegant, durable furniture that remains influential today.

The standardization of furniture production also led to the emergence of furniture catalogs and mail-order businesses, making it possible for consumers across different regions to access the same styles and qualities of furniture, democratizing interior design in unprecedented ways.

The transition from decorative Victorian styles to more practical designs marked a significant shift in furniture manufacturing during the Second Industrial Revolution. As mass production techniques evolved, elaborate hand-carved details and ornate embellishments gave way to cleaner lines and simpler forms. This transformation wasn’t merely aesthetic – it reflected the changing needs of society and the capabilities of new manufacturing processes.

Factory owners discovered that streamlined designs could be produced more efficiently and cost-effectively, making furniture accessible to a broader market. The focus shifted from showcasing craftsmanship through intricate details to emphasizing durability and functionality. Simple geometric patterns replaced busy florals, while straight lines superseded curved elements that were challenging to mass-produce.

This pivotal change laid the groundwork for modern furniture design, where form follows function. Today, many sought-after vintage industrial pieces from this era showcase the beauty of simplicity and practicality, making them valuable candidates for restoration and contemporary home styling.

The Second Industrial Revolution brought unprecedented advances in metal manufacturing, revolutionizing furniture design and production. The development of the Bessemer process in 1856 made steel production more efficient and cost-effective, enabling manufacturers to create stronger, more intricate furniture frames. This innovation led to the iconic industrial-style furniture that remains popular today.

Iron casting techniques also evolved significantly, allowing for more detailed decorative elements and sturdier construction. Manufacturers could now mass-produce elaborate bed frames, dining table bases, and chair components with consistent quality. The combination of steel and iron gave birth to versatile furniture pieces that balanced durability with aesthetic appeal.

These metalworking innovations influenced design aesthetics beyond just structural improvements. The ability to create thinner, stronger metal components led to more elegant furniture profiles while maintaining structural integrity. Victorian-era furniture makers particularly embraced these capabilities, incorporating ornate metalwork into their designs.

The legacy of these advancements continues to influence modern furniture design, with industrial-style pieces featuring exposed metal frames and raw steel finishes becoming increasingly sought-after in both residential and commercial spaces. Many original pieces from this era are now considered valuable antiques, prized for their craftsmanship and historical significance.

The mechanization of woodworking during the Second Industrial Revolution revolutionized furniture production, transforming it from a purely handcrafted process into an efficient manufacturing operation. Steam-powered machinery, including circular saws, planers, and lathes, enabled craftsmen to process wood with unprecedented speed and precision. This technological leap meant furniture pieces that once took days to create could now be completed in hours.

The introduction of standardized measurements and interchangeable parts brought consistency to furniture manufacturing. Machine-processed wood components could be cut to exact specifications, ensuring uniformity across production lines. This standardization made furniture more affordable and accessible to the growing middle class, while also establishing the foundation for modern mass production techniques.

Notable innovations included the band saw, which allowed for intricate curved cuts, and the mechanical jointer, which created perfectly straight edges for seamless joints. These advancements not only increased production efficiency but also introduced new design possibilities. The ability to create identical pieces consistently led to the development of matching furniture sets, a concept that remains popular in contemporary home furnishing.

The era’s machine-processed wood techniques continue to influence modern furniture manufacturing, though now enhanced by computer-controlled precision and automated systems.

Today’s modern industrial design trends celebrate the raw aesthetics and functional principles of the Second Industrial Revolution. Contemporary furniture makers are reviving historical manufacturing techniques while incorporating modern materials and sustainable practices. The industrial style emphasizes exposed metals, reclaimed wood, and mechanical elements that pay homage to factory equipment and machinery of the past.

Popular design elements include cast iron table bases, steel-framed chairs, and workbench-inspired dining tables. These pieces often feature distressed finishes, visible rivets, and mechanical components that showcase their construction methods. The style’s authenticity comes from combining vintage industrial artifacts with contemporary craftsmanship.

Restoration specialists are seeing increased demand for genuine industrial pieces from the late 19th and early 20th centuries. These items, often salvaged from old factories and warehouses, are being carefully restored while preserving their original character. The value of these authentic pieces continues to rise as more homeowners and businesses seek to incorporate industrial heritage into their spaces.

Commercial spaces particularly embrace this style, with restaurants, offices, and retail establishments featuring exposed brick walls, metal fixtures, and restored industrial furniture. This design approach creates an atmosphere that connects modern spaces with their historical industrial roots while maintaining functionality and durability.

Industrial Revolution-era furniture stands as a testament to quality craftsmanship and durability, with many pieces surviving well over a century of use. These items, characterized by their robust construction and quality materials, often showcase superior workmanship compared to many modern mass-produced pieces. The use of solid woods, traditional joinery techniques, and hand-finished details makes these pieces particularly valuable for restoration.

The restoration potential of industrial-era furniture is remarkably high, primarily due to the quality of materials used and the straightforward, functional designs. Many pieces from this period were constructed using old-growth timber, which is significantly more dense and durable than today’s commercially available wood. This superior material quality, combined with traditional construction methods like mortise and tenon joints, means that even severely damaged pieces can often be successfully restored.

The value of restored industrial furniture continues to rise, driven by growing appreciation for authentic period pieces and sustainable practices. Well-preserved or professionally restored items from this era can command premium prices in today’s market, often surpassing the cost of new furniture. This value retention makes restoration a worthwhile investment, particularly for signature pieces like cast iron machinery tables, factory stools, and timber workbenches that have been repurposed for modern homes and commercial spaces.

The Second Industrial Revolution’s impact on furniture design continues to resonate in today’s restoration practices. The manufacturing techniques developed during this transformative period – from mass production methods to innovative joinery systems – laid the groundwork for many furniture styles we now consider classics. Modern restoration specialists regularly encounter pieces from this era, with their distinctive combination of machine precision and architectural influence.

These industrial-era furniture pieces, characterized by their durability and functional design, have become highly sought-after in contemporary spaces. Their enduring appeal lies not just in their historical significance, but in their ability to complement modern interiors. When restoring these pieces, professionals must understand both the original manufacturing methods and the materials used to maintain authenticity while ensuring structural integrity.

The principles of efficiency and functionality that defined Second Industrial Revolution furniture design continue to influence modern manufacturing. For restoration experts, this historical knowledge is invaluable when working with both period pieces and contemporary furniture inspired by industrial aesthetics. Understanding these foundations helps ensure that restoration work preserves not only the physical piece but also its historical significance and design integrity.