Industrial digital twins are revolutionizing manufacturing operations by creating virtual replicas of physical assets, processes, and systems in real-time. This cutting-edge technology enables facility managers and business owners to monitor, analyze, and optimize their operations with unprecedented precision and foresight.

By combining sensor data, artificial intelligence, and advanced analytics, digital twins provide a dynamic, interactive model of industrial equipment and processes. This virtual representation allows organizations to simulate scenarios, predict maintenance needs, and make data-driven decisions without disrupting actual operations.

For commercial furniture manufacturers and facility managers, digital twins offer game-changing capabilities: real-time production monitoring, quality control optimization, and predictive maintenance that prevents costly downtime. The technology creates a bridge between physical and digital worlds, enabling teams to visualize complex processes, identify inefficiencies, and implement improvements with confidence.

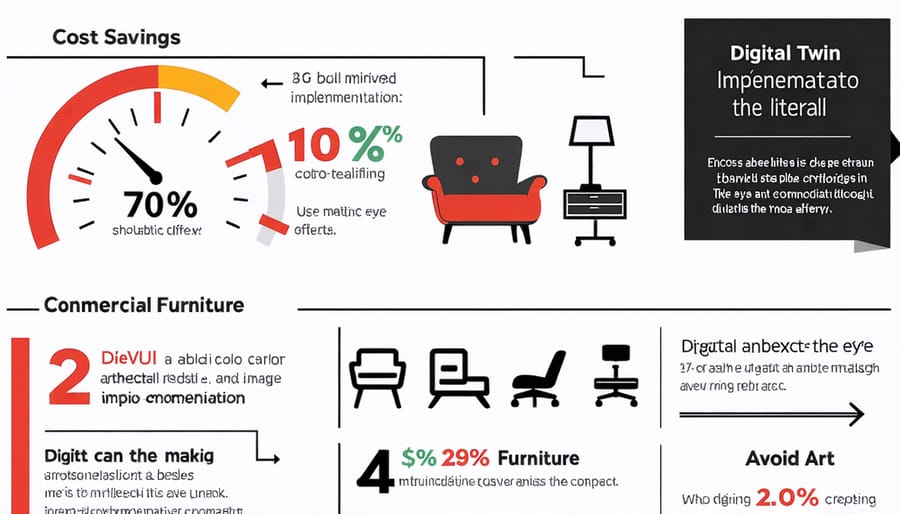

As Industry 4.0 continues to transform manufacturing, digital twins have emerged as a crucial tool for maintaining competitive advantage. Companies implementing this technology typically see 15-30% reduction in maintenance costs and up to 25% improvement in operational efficiency. The investment in digital twin technology isn’t just about keeping pace with innovation—it’s about securing a smarter, more profitable future for industrial operations.

Digital twins in the furniture industry revolutionize how we monitor and maintain commercial assets in real-time. These virtual replicas collect data through embedded sensors that track various parameters including usage patterns, weight distribution, and environmental conditions. For example, a digital twin of an office chair can monitor how many hours it’s been in use, the frequency of adjustments, and even unusual stress patterns that might indicate imminent failure.

The predictive maintenance capabilities are particularly valuable for facility managers. By analyzing historical data and current usage patterns, the system can forecast when specific components might need replacement or repair. This proactive approach helps prevent unexpected breakdowns and extends furniture lifespan. A hotel lobby sofa’s digital twin might alert management that the cushion support system is showing early signs of wear, allowing for scheduled maintenance before guests notice any deterioration.

The technology also enables efficient resource allocation by providing detailed insights into furniture utilization rates and maintenance schedules. Property managers can make data-driven decisions about furniture rotation, replacement cycles, and preventive maintenance, ultimately reducing operational costs while maintaining optimal functionality.

Digital twins revolutionize how businesses optimize workspace layout and maximize space utilization. By creating precise virtual replicas of physical spaces, facility managers can experiment with different furniture arrangements without moving a single piece. This technology enables real-time visualization of space modifications, helping businesses make data-driven decisions about their floor plans.

The system considers various factors such as traffic flow patterns, workspace ergonomics, and safety regulations when suggesting optimal layouts. For retail environments, digital twins can simulate customer movement patterns to identify prime product placement areas. In office settings, the technology helps balance the need for collaborative spaces with individual workstations while maintaining proper distancing requirements.

Companies report up to 30% improvement in space efficiency after implementing digital twin-based layout planning. The technology also reduces the time and labor costs associated with physical space reorganization by allowing managers to validate changes virtually before implementation. This proactive approach to space management ensures businesses maximize their real estate investment while creating comfortable, functional environments for employees and customers.

The foundation of an effective industrial digital twin system lies in its ability to collect and process real-time data from physical furniture assets. Modern sensors play a crucial role in this data collection process, with several types commonly deployed in commercial furniture monitoring.

IoT-enabled pressure sensors can detect weight distribution and usage patterns, helping predict wear and tear on seating surfaces. Environmental sensors monitor temperature, humidity, and air quality, which directly affect furniture longevity. Motion sensors track furniture movement and utilization rates, while smart tags with RFID or QR codes enable seamless asset tracking and maintenance history logging.

Advanced imaging sensors, including infrared cameras, can detect structural issues beneath upholstery surfaces before they become visible to the naked eye. Vibration sensors monitor the structural integrity of furniture joints and frameworks, particularly important for frequently moved items like stackable chairs and folding tables.

Data collection methods typically involve a combination of wireless and hardwired systems. WiFi-enabled sensors transmit data continuously to central monitoring stations, while Bluetooth beacons provide location-based tracking. Cloud-based platforms aggregate this information, creating comprehensive digital profiles of each furniture piece.

Integration protocols ensure seamless communication between different sensor types and the main digital twin platform, enabling real-time monitoring and predictive maintenance scheduling. This systematic approach to data collection forms the backbone of effective furniture asset management and preservation.

Creating virtual models for industrial digital twins begins with gathering detailed data about the physical furniture pieces and their operational environment. Advanced 3D scanning technology captures precise measurements and specifications, while sensors collect real-time performance data. These inputs are then processed through specialized modeling software to create accurate digital representations.

The development process typically involves three key stages: geometry modeling, behavior mapping, and environmental integration. During geometry modeling, every physical aspect of the furniture piece is digitally recreated, from its dimensions to surface textures. Behavior mapping involves programming how the virtual model responds to different conditions, such as weight distribution or temperature changes. Environmental integration ensures the digital twin accurately reflects its real-world surroundings and interactions with other equipment or systems.

Quality assurance plays a crucial role, with regular calibration between the physical asset and its digital counterpart ensuring accuracy. This ongoing validation process helps maintain the digital twin’s reliability for decision-making and predictive maintenance purposes. The result is a dynamic, interactive model that provides valuable insights for furniture management and maintenance planning.

Digital twins seamlessly integrate with existing furniture management systems and facility infrastructure through standardized protocols and APIs. This integration enables real-time data flow between physical assets and their digital counterparts, creating a comprehensive ecosystem for asset monitoring and management.

The connection process typically involves mapping existing sensors and control systems to the digital twin platform, establishing secure data channels, and configuring automated workflows. Modern digital twin solutions offer plug-and-play compatibility with common building management systems, inventory tracking software, and maintenance scheduling tools.

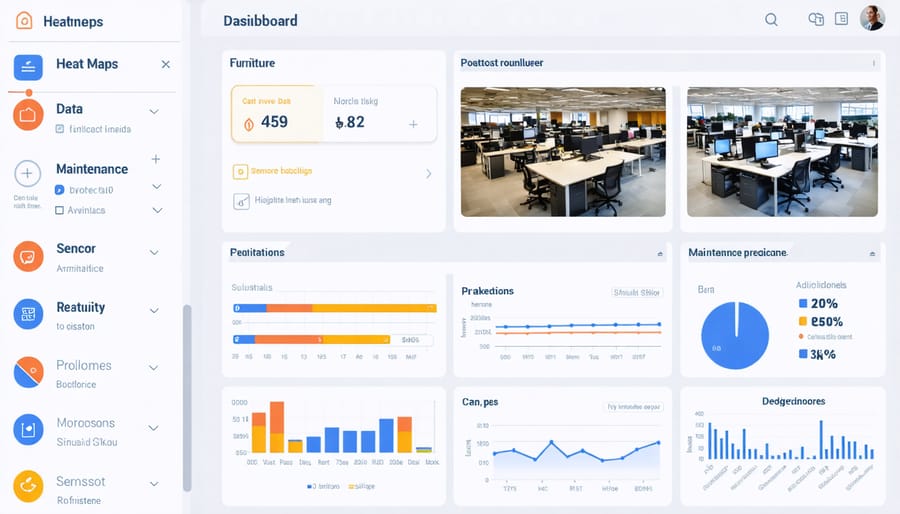

For facility managers, this means they can view and control their entire operation from a single dashboard. The system aggregates data from multiple sources, including temperature sensors, occupancy monitors, and equipment maintenance logs, presenting a unified view of facility performance. This integration also enables predictive maintenance alerts, automated inventory updates, and dynamic space utilization reports, making it easier to optimize operations and reduce costs while extending the lifespan of valuable furniture assets.

Digital twins are revolutionizing how businesses reduce maintenance costs while maximizing the lifespan of their commercial furniture assets. By creating virtual replicas of physical furniture pieces, companies can monitor wear patterns, predict potential failures, and schedule maintenance interventions before costly breakdowns occur.

This predictive approach transforms traditional reactive maintenance into a strategic operation. For instance, a hotel chain implementing digital twin technology for their lobby furniture reported a 40% reduction in emergency repair costs within the first year. The system detected early signs of fabric wear and structural stress, allowing for timely interventions that prevented complete furniture replacement.

The technology continuously collects data about furniture usage, environmental conditions, and wear patterns. This information helps facility managers make informed decisions about maintenance scheduling, optimal cleaning frequencies, and even furniture placement to minimize wear. A digital twin can alert staff when a piece of furniture is approaching its maintenance threshold, ensuring timely care while avoiding unnecessary servicing.

The cost benefits extend beyond immediate maintenance savings. By extending furniture lifespans through precise care timing, businesses can significantly delay replacement costs. Many facilities report furniture lasting 30-50% longer when managed through digital twin systems, representing substantial long-term savings in their operational budgets.

Digital twins in commercial furniture environments have revolutionized how businesses interact with their spaces and serve their customers. By creating virtual replicas of physical furniture showrooms and office layouts, companies can offer customers an immersive experience before making purchasing decisions. Customers can visualize different furniture arrangements, color schemes, and space configurations through interactive 3D models, reducing the uncertainty often associated with large furniture investments.

The technology enables real-time monitoring of furniture usage patterns, helping businesses optimize space utilization and improve customer comfort. For instance, in shared office environments, digital twins can track seating preferences and occupancy rates, leading to data-driven decisions about furniture placement and replacement cycles.

Customer satisfaction has seen notable improvements through personalized experiences. Digital twins allow for virtual product customization, where customers can experiment with different materials, finishes, and configurations before placing orders. This capability has significantly reduced return rates and increased customer confidence in their purchasing decisions.

The technology also enhances after-sales service by maintaining detailed records of furniture maintenance history, warranty information, and usage patterns. When issues arise, service teams can quickly access relevant data and provide more efficient solutions, leading to faster resolution times and improved customer satisfaction.

These improvements in customer experience have translated into measurable business benefits, including increased repeat business, positive reviews, and stronger customer loyalty.

The future of industrial digital twins is rapidly evolving, with several groundbreaking technologies poised to revolutionize how we manage and maintain commercial furniture assets. Artificial Intelligence and Machine Learning algorithms are becoming more sophisticated, enabling digital twins to predict maintenance needs and extend furniture lifespan with unprecedented accuracy.

Augmented Reality (AR) integration is making digital twins more accessible and interactive, allowing facility managers to visualize furniture conditions and maintenance requirements through mobile devices. This technology enables real-time collaboration between maintenance teams and stakeholders, streamlining decision-making processes.

IoT sensors are becoming smaller and more affordable, making it practical to outfit furniture pieces with monitoring capabilities. These sensors can track usage patterns, environmental conditions, and wear-and-tear metrics, feeding this data directly into the digital twin system.

Cloud computing advancements are enabling more robust data processing and storage capabilities, making digital twin implementations more scalable and cost-effective for businesses of all sizes. The integration of blockchain technology is also emerging as a secure way to maintain transparent maintenance records and asset histories.

Edge computing capabilities are reducing latency in digital twin operations, allowing for near-instantaneous updates and responses to changing conditions. This real-time monitoring and adjustment capability is particularly valuable in high-traffic commercial environments where furniture condition directly impacts business operations.

Successful scaling of digital twin implementation across multiple locations requires a methodical, phased approach. Start by identifying a pilot facility where the initial digital twin deployment can serve as a proof of concept. This allows teams to learn from early challenges and refine processes before broader rollout.

Once the pilot proves successful, create a standardized implementation playbook that outlines best practices, technical requirements, and training protocols. This documentation ensures consistency as you expand to additional locations while allowing for necessary customization based on specific facility needs.

Build a core team of digital twin champions who understand both the technology and your business operations. These experts can travel between locations to oversee new implementations and train local staff. Consider establishing a central command center to monitor multiple digital twins and coordinate responses across facilities.

Technology infrastructure must scale alongside your expansion. Invest in cloud-based platforms that can handle increasing data loads and ensure seamless integration between locations. Implement standardized data collection methods and naming conventions to maintain consistency across all digital twin instances.

Partner with vendors who have experience in multi-site deployments and can provide scalable solutions. Regular assessment of system performance and ROI at each location helps identify opportunities for optimization and ensures continued value as your digital twin network grows.

Remember that scaling is a journey, not a sprint. Maintain focus on quality over speed to build a robust and sustainable digital twin ecosystem.

Industrial digital twins represent a transformative technology that’s reshaping how businesses approach furniture manufacturing, maintenance, and facility management. By creating virtual replicas of physical assets, companies can optimize operations, predict maintenance needs, and make data-driven decisions with unprecedented accuracy.

Throughout this exploration, we’ve seen how digital twins enable real-time monitoring, enhance quality control, and streamline production processes. The technology’s ability to simulate scenarios and predict outcomes helps businesses reduce costs, minimize downtime, and improve overall efficiency. From small furniture workshops to large manufacturing facilities, the applications are scalable and adaptable to various needs.

The ROI potential of implementing digital twin technology is substantial, with benefits ranging from reduced maintenance costs to improved product quality and customer satisfaction. As the technology continues to evolve, early adopters are positioning themselves at the forefront of industry innovation.

For those considering implementing digital twins in their operations, the time to act is now. Start by assessing your current processes, identifying key areas for improvement, and consulting with technology providers who understand your specific needs. Remember that successful implementation requires a strategic approach, proper training, and commitment to digital transformation.

By embracing industrial digital twins, you’re not just investing in technology – you’re investing in the future of your business operations and competitive advantage.