Vacuum thermoforming revolutionizes modern furniture manufacturing by transforming flat plastic sheets into sophisticated, three-dimensional designs through precise heat application and air pressure control. This versatile process enables manufacturers to create everything from sleek chair shells to intricate decorative panels while maintaining consistency and reducing production costs.

Unlike traditional manufacturing methods, vacuum thermoforming offers unparalleled flexibility in creating complex shapes and textures, making it ideal for both small-batch custom projects and large-scale commercial production. The technology’s ability to replicate detailed patterns and maintain uniform thickness has made it a cornerstone of contemporary furniture design, particularly in creating ergonomic seating solutions and modular storage components.

For property managers and design professionals, understanding vacuum thermoforming opens up new possibilities in furniture selection and customization. The process combines durability with aesthetic appeal, producing pieces that withstand daily use while maintaining their visual appeal – a crucial consideration for both residential and commercial spaces.

The success of vacuum thermoforming relies heavily on selecting the right modern composite materials and having proper equipment in place. Common materials include ABS (Acrylonitrile Butadiene Styrene), HDPE (High-Density Polyethylene), and acrylic sheets, each offering unique properties for furniture applications. These thermoplastic materials typically come in sheets ranging from 1/16 to 1/4 inch thick.

Essential equipment includes a vacuum forming machine with a heating element, capable of reaching temperatures between 250-400°F (121-204°C). The machine must have a sturdy frame table with a perforated surface for vacuum suction and clamp frames to secure the plastic sheet. A vacuum pump system, typically ranging from 3-5 HP, ensures proper material forming around the mold.

Additional necessary tools include:

– Temperature controllers and gauges

– Cooling fans

– Plastic sheet storage racks

– Trimming tools and templates

– Safety equipment (heat-resistant gloves, eye protection)

– Mold release agents

– Pattern and mold materials (wood, aluminum, or composites)

Regular maintenance of this equipment ensures consistent quality and extends operational life.

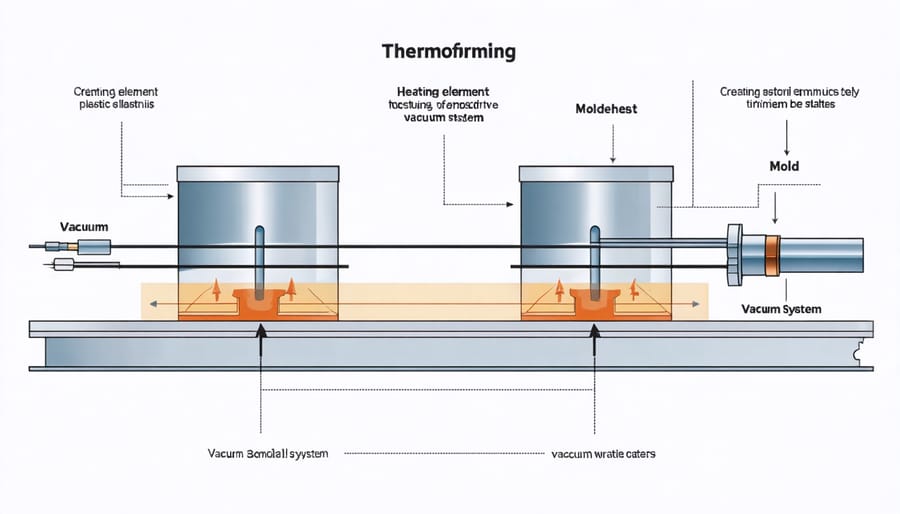

The vacuum thermoforming process follows a systematic sequence that ensures consistent, high-quality results. First, the plastic sheet material is carefully selected based on the desired specifications and loaded into the thermoforming machine. The sheet is then heated uniformly using overhead heaters until it reaches its optimal forming temperature, becoming soft and pliable.

Once heated, the plastic sheet is lowered onto a mold that contains small holes connected to a vacuum system. As the sheet makes contact with the mold, the vacuum is activated, drawing out the air between the sheet and the mold surface. This negative pressure forces the softened plastic to conform precisely to the mold’s shape and surface details.

The formed plastic is then cooled while still under vacuum pressure, allowing it to maintain its new shape. Cooling can be achieved through various methods, including fans, water cooling, or natural air cooling, depending on the material and production requirements. Once the plastic has sufficiently cooled and hardened, the vacuum is released, and the formed part is carefully removed from the mold.

Finally, any excess material is trimmed away using specialized cutting tools or automated systems, leaving a clean, finished edge. The completed piece undergoes quality inspection to ensure it meets all specifications before moving on to final assembly or packaging. This efficient process can be completed in minutes, making it ideal for both small-batch and high-volume production runs.

Vacuum thermoforming plays a vital role in creating numerous furniture components that we encounter daily. Chair backs and seats represent one of the most common applications, offering comfortable, ergonomic designs that can be produced efficiently at scale. These components are particularly prevalent in office furniture, where durability and consistent quality are essential.

Decorative wall panels and cabinet doors frequently utilize this technology to achieve sophisticated textures and patterns that would be costly or impossible to create through traditional manufacturing methods. The process also excels in producing drawer fronts, shelving units, and storage solutions that combine aesthetic appeal with practical functionality.

In modern furniture design, vacuum thermoformed components are increasingly used for creating unique architectural elements such as curved room dividers, modular storage systems, and contemporary table tops. The versatility of the process allows designers to incorporate complex shapes and seamless transitions that enhance both form and function.

For outdoor furniture, manufacturers rely on vacuum thermoforming to create weather-resistant pieces like pool loungers, patio chair components, and decorative garden furniture elements that maintain their appearance despite exposure to the elements.

Vacuum thermoforming opens up a world of creative possibilities in furniture design, allowing manufacturers to achieve unique shapes and forms that would be difficult or impossible with traditional manufacturing methods. When combined with other digital fabrication technologies, this process enables the creation of smooth, curved surfaces and intricate patterns that add both visual appeal and functionality to furniture pieces.

The process excels in producing seamless, flowing designs that can transform ordinary furniture into striking statement pieces. From ergonomically designed chair backs to decorative wall panels, vacuum thermoforming allows for consistent reproduction of complex shapes while maintaining precise detail and surface quality. This versatility makes it particularly valuable for creating custom furniture solutions that complement modern interior design trends.

Another notable advantage is the ability to incorporate textures and patterns directly into the forming process. Manufacturers can create pieces with embossed surfaces, wood grain effects, or geometric patterns that add depth and character to the final product. This eliminates the need for additional finishing processes while ensuring durability and uniformity across multiple pieces.

Vacuum thermoforming offers significant cost advantages compared to traditional furniture manufacturing methods, making it an attractive option for both small-scale and large production runs. The initial setup costs are relatively low, with basic equipment and tooling requiring modest investment compared to injection molding or CNC machining systems.

One of the most compelling benefits is the rapid production cycle. Once the mold is created and the process is optimized, manufacturers can produce multiple identical pieces in quick succession, significantly reducing labor costs and increasing output efficiency. This speed-to-market advantage is particularly valuable for businesses needing to respond quickly to changing market demands.

Material costs remain competitive, as thermoforming typically uses less raw material than traditional manufacturing methods. The process also generates minimal waste, contributing to sustainable furniture manufacturing practices and reducing overall production costs.

The versatility of vacuum thermoforming allows for the creation of complex shapes and detailed designs without the need for expensive tooling modifications. This flexibility translates to cost savings when developing new product lines or customizing existing designs. Additionally, the maintenance costs are generally lower than other manufacturing methods, with fewer moving parts and simpler mechanical systems to maintain.

However, it’s important to consider the limitations in terms of material thickness and detail precision when evaluating whether vacuum thermoforming is the right choice for specific furniture components. The initial mold cost, while lower than other methods, should still be factored into the overall project budget.

Vacuum thermoforming continues to revolutionize the furniture manufacturing industry, offering a perfect blend of efficiency, versatility, and cost-effectiveness. This technology has transformed how we approach furniture design, enabling manufacturers to create complex shapes and innovative designs that were previously difficult or impossible to achieve through traditional methods. As sustainability becomes increasingly important, vacuum thermoforming’s minimal waste production and ability to work with recycled materials positions it as a future-forward solution. With ongoing technological advancements and growing demand for customized furniture solutions, vacuum thermoforming is poised to play an even more significant role in meeting both residential and commercial furniture needs. The technique’s ability to produce high-quality, durable pieces while maintaining cost-effectiveness makes it an invaluable tool for modern furniture manufacturing, promising continued innovation and growth in the years to come.